解冻设备简介

Introduction to thawing equipment

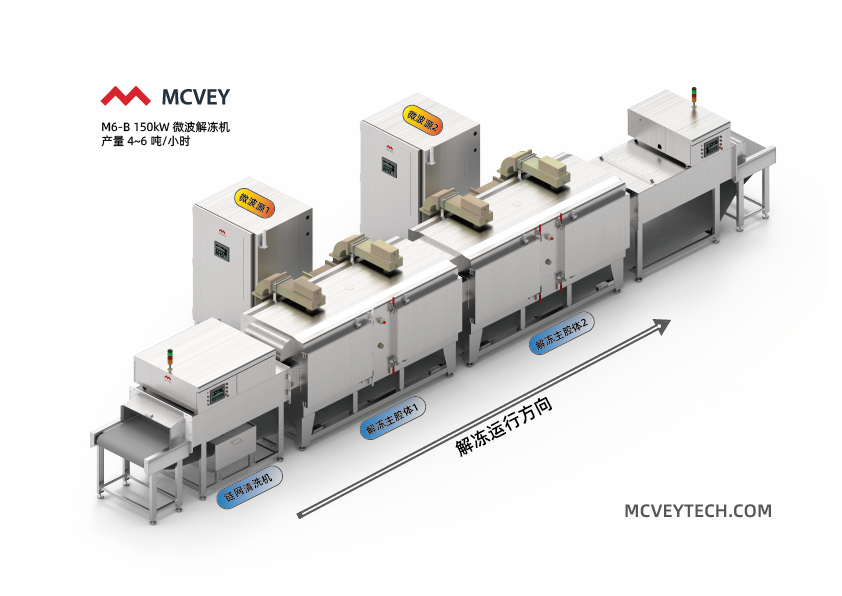

M6-B款微波解冻设备采用两台915Mhz/75kW开关稳压微波电源。

产量:4-6吨/小时,冻品温度从-18℃上升至-3℃(平均温度)。

微波解冻机由解冻主腔体、进出口抑制器、电器控制箱、链网和电机、微波传输波导、旋转天线等部分组成。

解冻主腔体采用304不锈钢制成,传输链网采用进口PP(聚丙烯)材质,符合食品行业安全标准。

The M6-B microwave thawing equipment uses two 915Mhz/75kW switch regulated microwave power supplies.

Production: 4-6 tons/hour, frozen product temperature increased from -18 ℃ to -3 ℃ (average temperature).

The microwave thawing machine consists of a thawing main chamber, inlet and outlet suppressors, electrical control box, chain network and motor, microwave transmission waveguide, rotating antenna, and other parts.

The thawing main chamber is made of 304 stainless steel, and the transmission chain network is made of imported PP (polypropylene) material, which meets the safety standards of the food industry.

冻肉物料由上料架进入,在解冻主腔体进行解冻,微波天线向物料发出微波进行辐射,经过腔体多次反射被物料吸收。

MCVEY采用德国引进的微波天线系统,使微波场在腔体中均匀分布,确保解冻物料的均匀性、高效性。

The frozen meat material enters from the feeding rack and is thawed in the main thawing chamber. The microwave antenna emits microwave radiation to the material, which is absorbed by the material through multiple reflections in the chamber.

MCVEY adopts a microwave antenna system imported from Germany, which evenly distributes the microwave field in the cavity, ensuring the uniformity and efficiency of thawed materials.

每台M6-B微波解冻设备需要2支M75kW磁控管,MCVEY先进的75kW磁控管技术给整个微波系统提供稳定的核心,具有极佳的长期使用成本优势。

Each M6-B microwave thawing equipment requires 2 M75kW magnetrons, MCVEY’s advanced 75kW magnetron technology provides a stable core for the entire microwave system, with excellent long-term cost advantages.

主要功能 Major Function

1)定制配方功能:根据不同的被解冻物料,设置好相应的解冻参数,工人只需选择物料的种类,进行一键操作启动设备

2)紧急停机功能:在设备的物料进出口和控制柜上配有黄色紧急停机按钮,当设备运行异常时可按下急停,保证安全生产

3)可视化操作:进料与出料端控制箱都配置有10英寸触摸显示屏,采用直观的方式动态显示物料位置、参数、状态以及故障信息

4)远程监测功能:具备使用以太网接口进行监测的功能;具备使用互联网或移动通信网进行远程监测的功能(可选)

5)除湿功能:腔体装有防水风机,可将腔体内的水蒸气迅速抽至腔体外

6)自动链网清洗装置:使用喷雾与高压气体进行清洁工作,达到食品安全自动化,无需人工清洗

1) Customized formula function: Based on different thawed materials, set corresponding thawing parameters. Workers only need to select the type of material and perform one click operation to start the equipment

2) Emergency stop function: The equipment is equipped with a yellow emergency stop button on the material inlet and outlet and control cabinet. When the equipment runs abnormally, the emergency stop can be pressed to ensure safe production

3) Visual operation: Both the feed and discharge control boxes are equipped with a 10 inch touch screen, which dynamically displays the material position, parameters, status, and fault information in an intuitive way

4) Remote monitoring function: equipped with the function of using Ethernet interface for monitoring; It has the function of remote monitoring using the Internet or mobile communication network (optional)

5) Dehumidification function: The chamber is equipped with a waterproof fan, which can quickly extract water vapor from the chamber to the outside of the chamber

6) Automatic chain net cleaning device: use spray and high-pressure gas for cleaning, to achieve food safety automation, without manual cleaning